Another project we didn’t want to deal with was added to the list. Our pump out was stopped when we attempted to open our holding tank screw cap. It would not budge. We ended up striping both the cap and our winch handle. We gave up, feeling defeated and still bloated.

Initial ideas

We ran out of time that night so we went home and thought of a few approaches to crack open this stupid cap.

- Release pressure – maybe there’s pressure in the tank pushing against the screw cap making it bind.

- Different tool – there’s still lots of good thread in the aluminum cap. Different winch handle, or is it possible to get a steel tool that has a better grip than our winch handle.

- Penetrating spray – soak the deck fill cap with a penetrating lubricant.

- Heat and cold – heat the deck fill sleeve and cool the deck fill cap to try and shrink the cap to allow a lubricant to sink in and release the cap.

- Nick and tap edge – make an indent on edge of cap and then use screwdriver/chisel with a hammer to try and tap open.

- Drill two holes and insert screws – with two screws in cap can place a metal bar between to use to try and twist open.

- Cut straight notch across entire deck screw cap – essentially turning the cap into a large flathead screw.

What didn’t work

We immediately started with the penetrating spray. A bit nervous about it sitting on the fiberglass so kept clearing it off right after spraying. Re-applied several times.

Grabbed some ice from our freezer and let it melt in the hole at the top of the deck cap. Thought about buying a can of compressed air (for dusting computer components) to super cool the cap. And wasn’t willing to try to heat the outside sleeve.

Went below to open up the holding tank to ensure there was no back pressure. Sometimes I am thankful that I have a terrible sense of smell.

The deck cap was still stuck and wouldn’t budge at all. We were trying to be as careful as possible to not strip the handle or cap any more. But as frustrations continued to rise and more curse words were being heard by our neighbours, it was time to step things up.

I took a large screwdriver and tapped in a nick in the “W” of “Waste”. Then put the screwdriver on an angle to try and tap open the cap counter-clockwise. This did nothing.

What did work

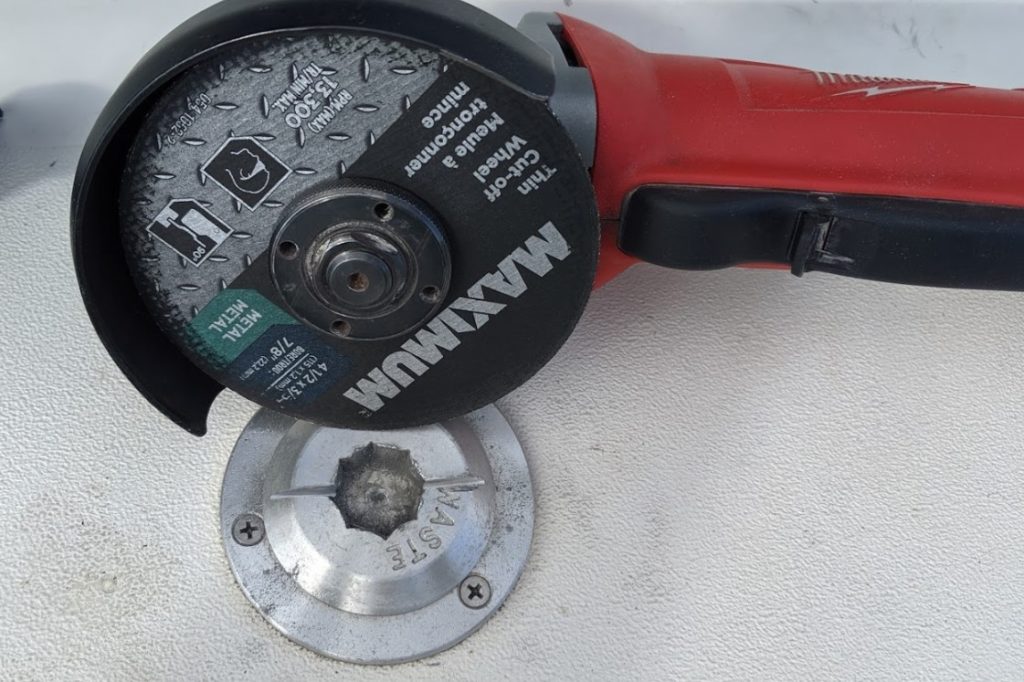

Time to bring out one of my favourite tools. My cordless angle grinder. This tool is the ultimate “fixing” tool when nothing else works.

As you can see I cut a notch straight across the top of the waste cap. Needed to make sure it was deep enough for my next tool to grab but not too deep that it would cut the cap in half.

I then used a large flat piece of stainless steel multi tool for opening deck caps and wedged it into the slot I cut. With a large pair of pliers pinched on top for leverage I slowly cranked on it. Watching carefully that I didn’t strip my notch in the aluminum cap; this would result in me hurtling my favourite tool into the water.

Success! With a little more pressure the cap moved. And after a few more careful turns it was starting to turn freely and eventually came out completely!

Lessons learned

This is the cap that nobody wants to touch and when it’s open, nobody wants to be around. But it does needs a little care and attention. You can see in the pic above the threads are pitted and corroded. I think just a little bit of grease on the threads would have prevented all of this.

I also noticed our winch handles are also aluminum and have a well used rounded edge. There’s a lot of play in all of our deck screw caps so even just a little bit of crud could cause the cap to strip a little bit. So I either need to buy a better tool or make the same cut in all my caps and buy a really really big flathead screwdriver. I’m joking about the second option.

Would like to hear your thoughts. What would you do?

October 18, 2019 at 10:55 am

I had the same problem on my 1990 CS 34. I tried multiple winch handles, the penetrating oil, the nick and screw diver and was about to give up when a friend on the boat next to me solved the problem. He found a piece of 3/4 square tube stock that fit into the cap perfectly. One tap with a hammer and a twist with an adjustable wrench and the cap was free.

Chances are that the waste cap is the only one that will ever seize and I keep the 3/4 tube stock on board, just in case.

October 18, 2019 at 4:21 pm

Hi John, that’s a brilliant idea. I’m now going to look for some 3/4″ square tube stock and keep it in my toolkit!

October 21, 2021 at 4:03 pm

i3DGear Marine makes a 3D printed stainless steel tool for this problem that fits on a standard 3/8″ socket drive. It can be used on an impact driver to ‘hammer’ out most stuck caps of this type. You can also put it on a 3/8″ socket drive with a long cheater bar to wrestle out a stuck cap. It can be ordered from our website.

October 21, 2021 at 4:05 pm

Hi Rick, I normally don’t like people promoting their products in the comments here, but you have what looks like a great product that I could have used! Didn’t even know this option existed. Would have saved me from destroying my cap!